MORE INFORMATION

- Special Report: Covering the Drain

- Entrapment Testing at aGlance

- Road to a Recall

- On the Right Track?

- On the List

These small pieces of plastic have recently generated huge headlines, but ensuring the safety of drain covers is much more complicated than the sound bites suggest.

Here is a short definition of each test and an explanation of the entrapment it is designed to stop.

A timeline of events that led to the drain cover recall.

The new version of the drain-cover standard is scheduled for release, but it may need some fine-tuning.

A list of the models named in CPSC’s recall.

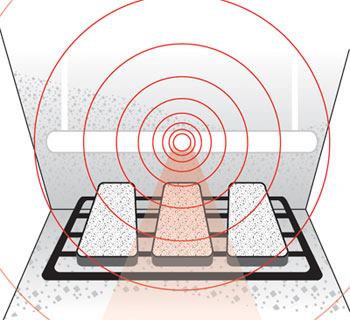

A key component to entrapment prevention is ensuring secure placement of drain covers.

Though this aspect of drain-cover design was not a factor in this year’s historic recall, it’s arguably the most important variable: If the suction fitting becomes broken or does’t stay in place, there is no protection for swimmers.

Indeed, a high percentage of entrapment cases involve a missing or broken drain cover, including two of the three tragedies that garnered support for the Virginia Graeme Baker Pool and Spa Safety Act.

To address this issue, the drain-cover standard includes a category of tests and design parameters related to the product’s durability against the abuses of users, exposure and time.

New to this section is a protocol addressing ultraviolet exposure. It calls for an 8-inch piece of plastic, called a “dog bone,” comprised of the same material used in suction-outlet covers. After exposing the bone to an amount of UV light equivalent to 15 years of Southern Arizona sun, the tech then determines to what extent the material has degraded by striking it with a calibrated machine.

A tensile-strength test is performed on other samples. If durability is reduced by more than 30 percent, the material automatically fails. If the loss of strength is less, the lab staff will then perform another round of tests on the drain cover itself, using a calculation based on how badly the material degraded in the first test.

This section of the standard also dictates the manner in which drain covers are to be attached to the wall or floor. Screws must be made of stainless steel graded 316 for corrosion resistance, and contain three or more threads. Although the current rewrite will probably maintain those specifications, the test itself will likely prove more rigorous, and many speculate that the three-thread screws will not pass.

Some entrapment incidents were caused by inferior, off-the-shelf replacement screws that became loose over time and dislodged the drain covers. To prevent this, the new version of the standard may require that covers be imprinted with warnings instructing professionals to use only screws provided by the manufacturer.