Insert the dowels

Cut the dowels so they’re long enough. Each should measure at least 30 times the diameter of the steel. Some prefer 40 times.

This length helps secure the existing structure against natural movement that will occur as the new feature settles. “Let’s say you have this pool that’s been there 10 years, and now you’re adding this new 10-foot section,” Peterson says. “Maybe the new section is on softer soil than the original pool. The original pool isn’t going to move — it’s been sitting in that soil a long time. But the new section might want to settle down. So the top of the wall will pull on all that steel. If that steel is only embedded 6 inches into the existing shell, it’s just going to pull right now.”

When attaching a non-structural element, installers could dowel the bars as shallow as 6 inches, Peterson says.

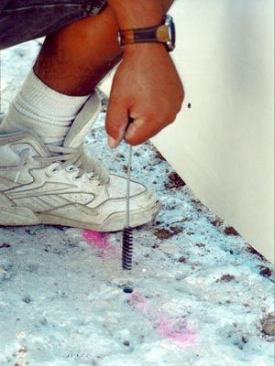

Take care when inserting the dowels. “You should be kind of rolling and tapping as you’re putting it in there,” Toth says, “because you want good expression — you want the epoxy to cover the rebar really well.”

Make sure to push until it gets to the end of the hole. Any voids in the concrete can compromise its integrity.

Time this step so the epoxy has had a little time to set, but not too much. “My crews drill all the holes, then they’ll fill about 10 holes, then place 10 pieces,” Toth says. When doing this, excess epoxy will probably ooze out from inside the holes. Don’t clean it up while still wet. It’s easier to allow it to try, then chip it off later, Peterson says.