As unique as each installation is, all pools require the same basic calculations before a pump can be chosen. First, you must determine factors such as the pool’s volume and capacity, the required water flow rate for proper water turnover and the system’s total dynamic head. Then, you must ensure that the suction pipe size can handle the flow at a safe velocity.

Even if you’re replacing a pump in an existing system, it’s best to go through the simple calculations provided here to be sure you’re installing the right pump for that pool.

Formulas

How to figure pool volume

Rectangular or square pool:

length x width x average depth* = pool volume

Oval pool:

1/2 length x 1/2 width x 3.14 (pi) x average depth = pool volume

Circular pool:

radius x radius x 3.14 (pi) x average depth = pool volume

Free-form or irregular pool: Use the equation for an oval or rectangle,

as needed. To be more precise, measure the pool with a planimeter,

but that’s not necessary; a close estimate is all that’s needed.

* To find the average depth of a slope-floored pool, measure the depths at both ends, add them together and divide by 2 .

How to measure pool capacity

Pool volume x 7.48 = pool capacity in gallons

How to determine water flow rate:

Flow rate per hour ÷ 60 = flow rate per minute

Pool volume: To determine pool volume (the amount of space measured in cubic feet), you’ll need the basic pool dimensions. If you don’t have the specs handy, measure the pool. Don’t be too concerned about absolute accuracy because close estimates will be adequate for these equations. (If you must estimate, be sure not to underestimate.) For simplicity, make your measurements in feet and tenths of feet to keep the calculations in easy decimal form.

Naturally, the pool’s shape will determine which equation to use to calculate the volume in total cubic feet. To figure the volume of oval, circular, square or rectangular, and irregular or free-form pools, see “Formulas” (below) or use a smartphone app.

Pool capacity: Next, determine the pool capacity (the number of gallons it will hold), keeping in mind that there are 7.48 gallons in 1 cubic foot of water. Simply multiply the volume of the pool by 7.48.

Flow rate: Now it’s time to determine the flow rate needed to circulate the pool water in a timely manner. The flow rate is simply how many gallons of water per minute the pump moves. It is tied into the turnover rate, that is, the amount of time it takes to move the entire capacity of the pool through the system. The recommended turnover time varies depending upon region and individual preferences, but eight hours can be considered an adequate turnover time. (To calculate the flow rate, see “Formulas.”)

Total dynamic head: Total dynamic head (TDH) is the sum of the resistance encountered by water flowing through the pool’s circulation system. Resistance is applied throughout the system, such as when water flows through elbows, fittings, valves, equipment and even through straight lengths of pipe. The TDH will affect flow rate and therefore is an important factor in selecting the right pump. Match the TDH of the system with the TDH of the pump.

All components in the circulation system, from the skimmer and main drain to the return inlets, must be factored into TDH calculations. Referring to the circulation system blueprints, list every component and dimension, including the total length and size of PVC pipe and copper pipe, the skimmer and drains, 45-degree elbows, 90-degree elbows, gate valves, backwash valves, and the size and type of filter and heater.

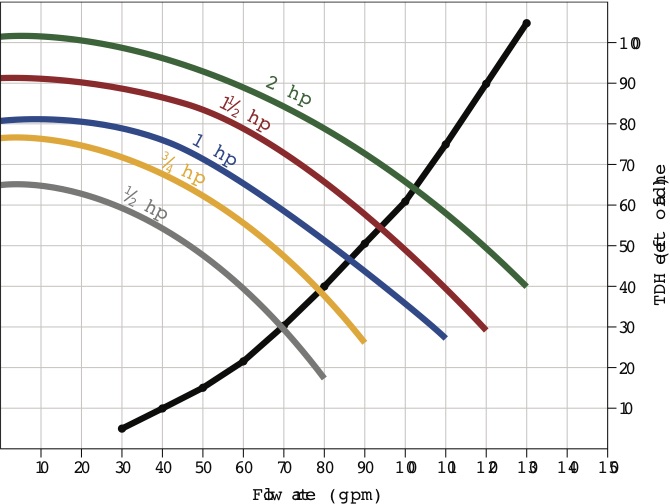

Consult the pump manufacturer’s head-loss charts to find the appropriate value for each component. Most manufacturers have developed their own methods for interpreting a pool’s needs, so contact them to obtain charts showing their preferred techniques (see sample charts on this page). Once your list of values is com plete, add them together; their sum is the total dynamic head of the system.

Updating the pump

Pumps today are far more efficient than they were a decade ago. That can prove to be an issue when trying to replace an older pump.

Horsepower is no longer related to power output, according to pump manufacturers. Flow dynamics have improved considerably. If you have a 15-year-old pump that is 2-horsepower and compare it with a contemporary 2-horsepower pump, you’ll have wildly different flow rates. The newer pump will move substantially more water.

Consequently, service technicians can make serious errors if they simply replace old pumps with new ones of identical horsepower. It could result in having too much velocity in the pipe.

New designs and materials have been responsible for the improvements in pool pumps. Falling by the wayside is the old bronze, open-face impeller. In its place are models that use closed-face impellers.

The older, open-faced impeller pumps used the front part of the pump housing, aka “the volute,” to create the actual pump action. As the impeller wore from friction and/or low pH, a bigger gap would form between the fins and impeller, and it would begin to pump less and less water.

Oddly, on pools where an open-faced impeller pump was oversized to begin with, the wear and tear actually would bring the flow-rate specs to where they should be. However, this stroke of luck should not be relied on when sizing pumps today. Because the modern plastic impellers are relatively impervious to wear, it’s even more important to get it right the first time.

If you do not know what’s under the deck, there is another option to calculate the TDH. Just use a pressure meter and this simple formula:

1. Check the influent pressure of the filter tank and multiply that number by 2.31.

2. Next, use the meter to take a vacuum reading on the pump suction line and multiply that number by 1.13.

3. Add these two numbers together to get the system’s TDH. For example, if the pressure reading is 12 psi, multiply that by 2.31 to get 27.72. If the vacuum reading is 5” mercury, multiply that by 1.13 and you’ll get 5.65.

4. Add the two results together: 27.72 + 5.65 = 33.37 total feet of head.

Consult the charts

After making these calculations, the rest is easy. Consult the pump manufacturer’s performance curve chart (see “System Head Curve” below). Using the flow rate and TDH numbers, determine the pump model with the appropriate horsepower.

Keep in mind, however, that these charts vary from manufacturer to manufacturer. You cannot consult a pump curve chart from Company A and then use that information to buy the same horsepower pump from Company B. It’s unlikely they’ll be the same.

While you’ll need a pump big enough to do the job, be careful not to exceed the maximum flow rate recommended for the plumbing, filter and heater. If water is pumped through the system at too high a velocity, it may damage the equipment, cause cavitation that may harm the pump, or strip the metal from copper pipes, producing leaks and copper stains.

Pool piping must be of the correct size to handle the needed flow rate without causing the water to flow too fast. Water velocity should not exceed 8 feet per second for discharge (pressure) piping or 6 feet per second for suction piping when PVC piping is used. (This complies with the new California Standards, which went into effect in January 2008.) In the case of copper piping, the velocity should in no case exceed 8 feet per second, according to APSP’s residential pool standard.

Symptoms, Causes and Procedures

Symptom: Noisy pump

Cause: Undersized influent piping; Blockage in influent line/full pump strainer basket; Air lines leak in influent line; Unsecure/unlevel base

Procedure: Compare pump size to pipe size; downsize the impeller and defuser if possible. Check the line and basket; remove any obstructions. Find and repair leak. Ensure pump sits level; secure it to equipment pad to avoid vibration.

Symptom: Noisy pump

Cause: Insufficient electric voltage; Loose electrical connections; Two-speed pump in low speed

Procedure: Check voltage with voltmeter at the motor terminals, the ground wire and the meter while pump is running; check wiring instructions and consult electric company, if necessary. Disconnect power and check for loose electrical connections. Switch pump to high speed.

These guidelines were prepared from materials provided by Hayward Pool Products Inc., ITT Marlow Leisure Products, and Pentair Aquatic Systems.

Up to speed

Just a few more points to ponder before deciding which pump brand you want.

Two-speed pumps, which are popular in the spa sector, also are being used on residential pool systems for increased energy efficiency. Such pumps typically are run on low speed for normal circulation and filtration, then switched to high speed to operate an automatic cleaner or when a heavy bather load dictates increased filtration is necessary.

New on the market are variable-speed pumps. These pumps have three main components: a wet end, a motor and a drive. The drive separates this pump from standard pump models. The drive is engineered to find the optimum flow for a given task — whether it requires high flow such as when operating spa jets, or a lower level such as what’s needed to perform basic circulation. Using the optimal flow minimizes energy consumption.

Regardless of the pump type used, the pump and electric motor typically are sold as a single unit. If you need to replace just the pump — or just the motor — be sure to keep three factors in mind: the mounting face, the shaft and the horsepower (which will be regulated by the energy draw needed by the pump impeller).

Acknowledgements: Technical information was provided by Baker Hydro, Hayward Pool Products Inc., Jacuzzi, Pentair Aquatic Systems, and Premier Spring Water Inc.