Make sure epoxy doweling is the appropriate solution

This process is key to many remodels, but it isn’t right for every project.

“We use it for adding steps, benches, artificial rockwork, filling in the floors — mostly things that are not related to the shell or its structural integrity,” says David Peterson, president/CEO of Watershape Consulting in San Diego.

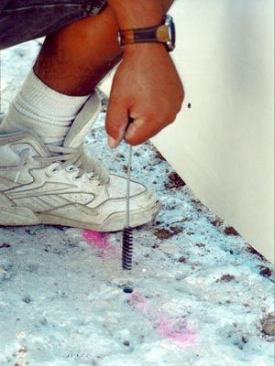

Some prefer not to use this method on structural elements, such as adding a spa or waterfeature, particularly when the addition is more than a few feet. Say, for instance, you wanted to add 10 feet of length to a pool. Intuition would say that you could knock out one end of the pool, add the 10 feet to each of the wide walls, epoxy doweling new to old, and then add the new end wall. However, this poses a problem. To maintain structural integrity, the installer must use rebar dowels measuring 30 to 40 times the diameter of the steel.

“It’s pretty tough to drill a dowel 20” for putting in a half-inch bar,” Peterson says.

In those cases, he believes it’s better to remove the concrete at the end of the pool while being sure to maintain the existing rebar. Bend the rebar back from the end of the pool so it sits on the sidewalls. This way, crews can tie the new steel cage to the old, then shoot the new shotcrete or gunite over it.

You also shouldn’t dowel into a structure that’s too thin. “If you’re adjoining to a sidewalk and it’s only 4 inches thick, I wouldn’t dowel that,” says Steve Toth, owner of Acclaim Pools in The Woodlands, Texas. “It will only cause the thing to fracture. You want to maintain the same rule as with gunite — you want a minimum of 3 inches on both sides of the steel.”